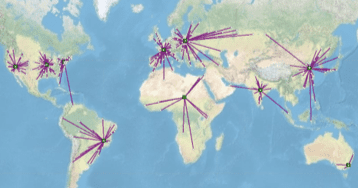

With supply chain costs on the rise and the pressure increasing to get products to market cheaper, ed quicker, and with a reduced carbon footprint, performing supply chain design projects provide an innovative and cost effective way to identify and test alternative scenarios. Analyzing our supply chains at the strategic and tactical levels can provide both operational efficiencies and a competitive advantage. But it’s not that easy. Global supply chains are becoming increasingly more complex, which is making the design projects more difficult, expensive, and time-consuming to execute with no guarantee the identified savings will ever be realized.

With supply chain costs on the rise and the pressure increasing to get products to market cheaper, ed quicker, and with a reduced carbon footprint, performing supply chain design projects provide an innovative and cost effective way to identify and test alternative scenarios. Analyzing our supply chains at the strategic and tactical levels can provide both operational efficiencies and a competitive advantage. But it’s not that easy. Global supply chains are becoming increasingly more complex, which is making the design projects more difficult, expensive, and time-consuming to execute with no guarantee the identified savings will ever be realized.

Here are five common supply chain design project mistakes with suggestions how to plan for and resolve:

- Organizational Buy-In: With supply chains spanning the globe, they also stretch across the organization. As supply chains have become longer and more complex, companies have managed that complexity by breaking up the supply chains into pieces and giving the responsibility to manage the individual parts to different entities often in faraway locations. In addition to obvious cultural and language challenges that could arise working between cross-regional and international teams, most likely the teams will also have their own priorities and initiatives. Ensuring they understand and buy-in to the business case of the supply chain design project is paramount. They don’t have to match the passion and drive of the project initiating team. They just have to be committed to fulfilling their role in the project. Tools such as a well defined project charter, stakeholder classification models, stakeholder register, and a stakeholder engagement matrix can all be used to plan, engage and mange stakeholders regardless the size of their role in the project.

- Objectives/Scope Clarity: The project charter has been approved with a project purpose and description, objectives, a justification, and high-level requirements, risks, and milestones. Everyone is excited and wants to dive immediately into the work. But not so fast. Make sure the objectives are all measurable with the required success criteria defined. The objectives are the starting point for the scenarios that will deliver the savings. Vague objectives will increase the number of scenarios as the team searches where to look for the expected savings. A preponderance of scenarios creates more internal preparation and management and overall weaker final deliverables because it stretches the stakeholders’ capacities to digest information and understand the output. Keep the project charter and scope statement as two distinct documents. Although they contain similar information, they are a different level. The scope statement should be a detailed description of things like the acceptance criteria, deliverables, constraints, and assumptions. Don’t worry about limiting creative thinking. It is much easier to think outside the box and discover along the way when the box is clearly defined.

- Resource Availability: With supply chains touching so many different parts of the organization, most likely the talent and support required to do supply chain design projects will as well. Project teams usually function at the highest level when co-located, but in today’s global economy that is just not feasible. Advancements in technology and the development and comfort with digital communication have mitigated this impact, but a gap still exists and is a significant risk in most projects. This makes it critical to identify the type and amount of expertise needed and the resources who possess it. Approach building the team as a procurement exercise. List multiple sources and don’t be afraid to include consultants if resources are thin. Prioritize and rank the resources and secure the best possible available one for each role. There might be a cost impact using external resources, but with the amount of capital at stake in global supply chains, spending money on resources to get the project done quickly and correctly is an easy business case to justify.

- Data Accuracy/Completness: Data collection, analyzing, and cleansing are usually the most time-consuming activities of supply chain design projects…or maybe it just seems that way because it so frustrating. We live in the information age, yet we never seem to have the right data. It always seems to be either incorrect or incomplete in some way or the other. We may have the piece we are responsible for, but just as many of the resources and buy-in required for success lie in other parts of the organization, so does the data. And getting that data? There is a better chance of walking into a Swiss bank with only a library card and getting access to an account. For as dispassionate as computers and data are supposed to be, the people in control of them are quite the opposite when someone requests access even if the person works for the same company. The earlier in the project we can identify the data requirements and link them to their origin and track in a requirements traceability matrix or similar document, the greater chance for success.

- Sub-Optimization: Most supply chain design projects begin with a simple goal: to reduce X or decrease Y. But the complexity inherent in the projects due to the organizational structure, resource availability, and data collection required to plan and execute make the goals difficult to realize. The easiest thing to do to reduce the complexity is narrow the scope by including only the things that we already have control of. The problem is that while this might be easy, it is also very dangerous. Resist the urge to sub-optimize and push costs and other benefits down in one area only to have them increase in another. Managing organizational complexity of supply chains might require dividing the supply chains and delegating the responsibility to manage them, but achieving savings in supply chain design projects is about putting the supply chains back together and looking at the total logistics cost, time, and emissions.

We shouldn’t let the complexity of our supply chains keep us from realizing the untapped strategic and tactical opportunities. Contact Trubelo Development for more information on the benefits of supply chain design. Trubelo is a business & creative development and project management company founded to help businesses and individuals convert ideas to results.